Description

Details

Timing Engine Tool FIAT STILO 2,4 BENZIN/ALFA ROMEO 1,6 ECO 105 HP PETROL ENGINE - ZR-36ETTS266 - ZIMBER TOOLS.

Model:

Fiat: 2.4 20v Stilo, Thesys Alfa Romeo: 147 1.6 ECO 105 HP

Engine Code:

Fiat: 192A2.000 Alfa Romeo: 372.03

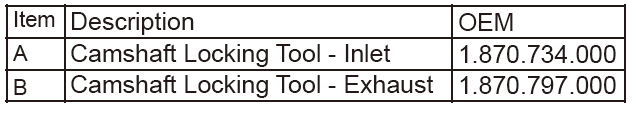

Item Description OEM

A Camshaft Locking Tool -

Inlet

1.870.734.000

B Camshaft Locking Tool -

Exhaust

1.870.797.000

Instruction:

Removal

1. Remove:

-RH front wheel

-Engine cover

-Auxiliary drive belt

-Auxiliary drive belt guide pulley

-Crankshaft pulley

-Timing belt upper cover

-Ignition coils

-Cylinder head cover

-Center spark plug - cylinder No.1

2. Insert dial gauge in No.1 cylinder center spark

plug hole. Turn crankshaft slowly to TDC on No.1

cylinder.

3. Ensure marks on belt aligned with marks on

sprockets

4. Slacken tensioner sprocket nut.

5. Remove timing belt.

Note: Mark direction of rotation on belt with chalk if

belt is to be reused.

Installation

1. Ensure crankshaft at TDC on No.1 cylinder. Use

dial gauge.

2. Hold inlet camshaft sprocket:

-Models with variable valve timing (except 155): use

Inlet Camshaft Sprocket Holding Tool. Slacken

camshaft sprocket bolt(s).

-Models without variable valve timing (except 155):

use Camshaft Sprocket Holding Tool

-155: use Camshaft Sprocket Holding Tool. Slacken

camshaft sprocket bolt(s).

3. Hold exhaust camshaft sprocket:

-Except 155: use Exhaust Camshaft Sprocket Holding

Tool. Slacken camshaft sprocket bolt(s).

-155: use Camshaft Sprocket Holding Tool. Slacken

camshaft sprocket bolt(s).

4. Except 147: remove third bearing cap from each

(A) and (B).

5. 147: Remove second (A) bearing cap and third

(B) bearing cap.

Note: Mark bearing caps before removal for

identification.

6. Fit (A) and (B) in place of bearing caps

- 1.6: Camshaft Locking Tool (Inlet or Exhaust)

Note: Ensure locking tools aligned with respective

cam profiles to prevent damage. Before fitting belt

ensure camshaft sprockets turned fully clockwise.

7. Fit timing belt in anti-clockwise direction,

starting at crankshaft sprocket.

Note: Ensure directional arrows point in direction

of rotation.

8. Ensure marks on belt aligned with marks on

sprockets.

9. Tension timing belt to maximum.

10. Tighten tensioner sprocket nut.

11. Hold inlet camshaft sprocket:

- Models with variable valve timing (except 155):

use Inlet Camshaft Sprocket Holding Tool.

- Models without variable valve timing (except 155):

use Camshaft Sprocket Holding Tool.

- 155: use Camshaft Sprocket Holding Tool

12. Tighten inlet amshaft sprocket bolt(s).

- Except 147: 100 - 124 Nm

- 147: 108 - 132 Nm

- M6 bolts - except 156: 10 Nm

- M6 bolts - 156: 12 Nm

13. Hold exhaust camshaft sprocket:

- Except 155: use Exhaust Camshaft Sprocket

Holding Tool.

- 155: use Camshaft Sprocket Holding Tool.

14. Tighten exhaust camshaft sprocket bolt(s).

-Except 147: 100 - 124 Nm

- 147: 108 - 132 Nm

- M6 bolts - except 156: 10 Nm

- M6 bolts - 156: 12 Nm

15. Remove:

- Dial Gauge

- Camshaft Locking Tool (Inlet and Exhaust)

16. Fit bearing caps in correct locations.

17. Lubricate camshaft bearing cap bolts. Tighten

bolts. Except 147: 13 - 16 Nm. 147: 14 - 17 Nm.

18. Turn crankshaft two turns clockwise to TDC on

No.1 cylinder. 156: use Crankshaft Sprocket Adaptor.

19. Ensure timing marks aligned.

20. Fit tensioning tool.

21. Slacken tensioner sprocket nut.

22. Turn tensioner sprocket anti-clockwise until

pointer aligned with hole in base plate.

23. Tighten tensioner sprocket nut.

- Except 147: 21 - 26 Nm

- 147: 23 - 28 Nm

24. Turn crankshaft two turns clockwise to TDC on

No.1 cylinder.

25. Ensure timing marks aligned

26. Install components in reverse order of removal.

27. Tighten crankshaft pulley bolts. Tightening

torque: 24 - 29 Nm.